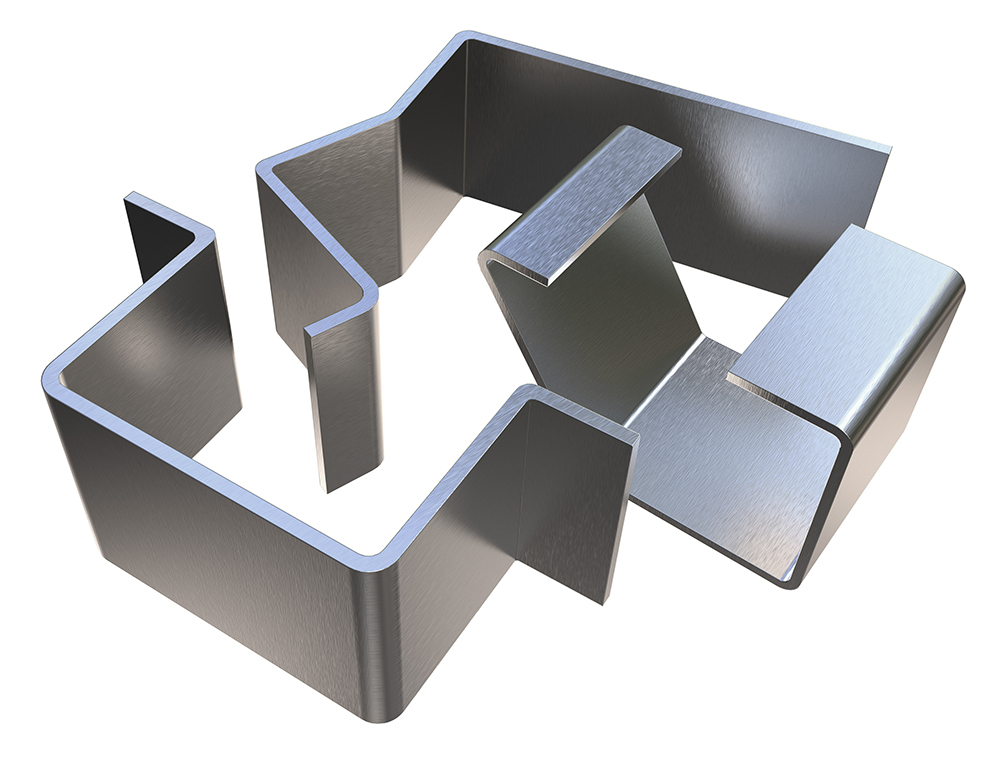

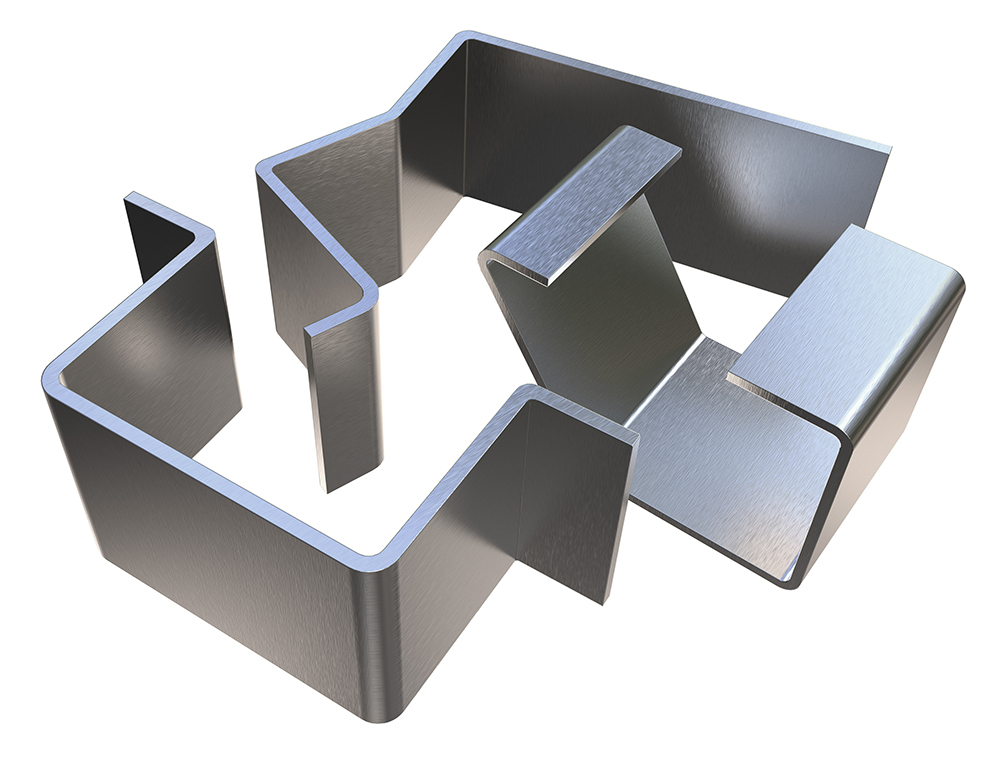

Is the size as expected? Do the corner pieces fit together seamlessly? Great if the welder gives the spatial figure to be made the right shape with the right size.

The underlying theory of constructing sheet unfoldings is always the same. From the spatial form , the trick is to always look for the true lengths of the important projection lines. The true lengths constructed from the projection lines are interconnected by contour lines and in this way the flat pattern is constructed. This technique is based on the construction method with "ruler and a pair of compasses". In a 2D CAD program, of course, the same technique can be applied as deconstruction with ruler and a pair of compasses, but then digitally.

Making a good sheet unfolding or flat pattern starts with determining the flat pattern size. This flat pattern size is the total length of the flat sheet before it is bended. Imagine you bend a metal sheet of 100 millimeters exactly in the middle with a bending angle of 90 degrees. The result is a corner profile. When measuring the two sides, these are added together not 100 millimeters but slightly larger. Why is that? The underlying theory is the "bend allowence" that occurs during the bending process. The bend allowence depends on, among other things, the material type, the rolling direction, the bending tools to be used and the material thickness. These factors are combined in the so-called k factor.

Good knowledge of the k factor and underlying theory of unfolding metal sheets is necessary for the production of plate related products. The specialists of OutShape have managed to intuitively combine the theory of construction with "ruler and a pair of compasses" and the k factor in a cloud solution. With this cloud software, the OutShape engineers have developed a powerful tool to easily produce sheet unfoldings from any profile that are "cut" at any imaginary angle. Online and without the use of CAD software directly to a DXF file. For more information and a free trial account, visit www.outshape.com. Also for Flanges, truncated cones etc..